- +966 59 538 6814

- info@tpw-ksa.com

Swing Shearing

Swing Shearing – For metals with a thickness (0.5 to 16 mm) we employ our powerful plate cutting machines which can be used over a variety of applications. At TPW we use the latest technology so that our plate Swing Shearing processes is at the top of their game. Through skills of our experienced operators we can produce precision cuts with clean edges.

Mild Steel Capacity

MS 16 mm Thick X 3000 mm

Stainless Steel Capacity

8 mm Thick X 2000 mm

WHAT CAN WE CUT?

TPW offers a complete end-to-end steel solution service and can produce products to meet any customer specification. Examples of commonly cut products include

- All Kind of Metal Sheets

- Bars

- Tubes

- Structural steel products

- Cladding

- Panels

- Hollow box sections

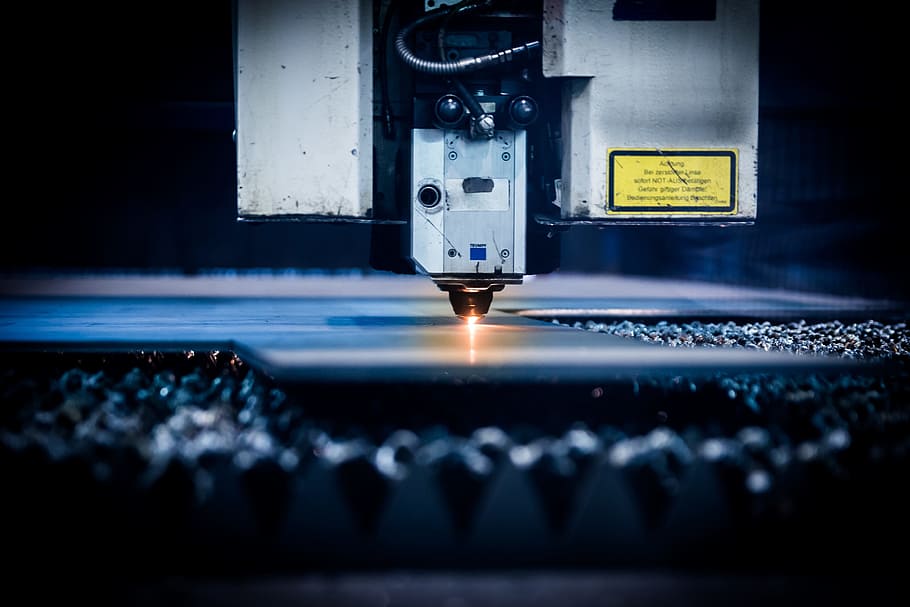

PLASMA CUTTING

What is Plasma Cutting?

This method of cutting relies on a process whereby highly pressurised inert gases are blown through an electrical arc which creates a state known as plasma. The temperature of plasma is extremely hot reaching temperatures of up to 20,000°C and because the metal being cut conducts the electrical arc, the plasma is directed onto the localised area at speed producing a powerful separation force. To ensure a clean cut we also employ an additional jet of ionised gas for the purpose of clearing the cutting incision of molten metal.

WHAT CAN WE CUT?

TPW offers a complete end-to-end steel solution service and can produce products to meet any customer specification. Examples of commonly cut products include

- All Kind of Metal Sheets

- Bars

- Tubes

- Structural steel products

- Cladding

- Panels

- Hollow box sections

Experts in plasma cutting

Plasma cutting is one of many cutting methods we employ at TPW as part of our extensive steel and metal fabrication offer. With a workforce of trained and experienced plasma cutting specialists, you can be sure that your requirements will be carried out to a high standard.

WHAT METALS CAN BE CUT WITH PLASMA?

Electrically conductive metals can be cut using plasma. The force of the plasma is applied through the electrical arc which must make contact with the metal. We can cut:

- Iron

- Aluminium

- Copper

- Brass

- Titanium

- Lead

- Cast iron

- Zinc

- Various alloys

WHAT IS PLASMA CUTTING USED FOR AND WHAT ARE THE BENEFITS?

Being able to cut through thick electro conductive metals makes plasma the perfect option for manufacturing:

- Balconies

- Canopies

- Durbar Plates

- Steel frames